Major Research 2A Research on Enhancement of Port and Airport Performance for Industrial Competitiveness

Background and Objectives

PARI is responsible for research and development to help improve the functions of ports, harbors, and airports across Japan, as part of the country's efforts to improve the international competitiveness of its industries and promote port, harbor, and airport development in an efficient and effective manner, as they are vital to the daily activities of the nation's citizens. PARI's research in these areas covers the following subthemes and goals that are relevant to Japan's international competitiveness, encompassing the country's global strategic port and harbor policy, improvement of airport functions in the Metropolitan Area (improvement of Haneda Airport), infrastructure export capability, etc. These topics are comprehensively studied by various departments of PARI as part of its overall R&D policy.

Research Topics

Research and development were conducted on the following topics to improve the port and airport functions in order to ensure their global competitiveness. For the particular objective of improving container terminal productivity, we are developing a container damage inspection system, evaluating numerical simulations of terminals where ICT, etc. are used, and studying various implementation plans as part of our efforts to promote digital transformation at ports and harbors, improve their operational efficiency, facilitate the implementation of environmental measures, and enhance their overall functions.

Activities in FY 2020

ⅰ. Proposal of evaluation method to estimate the productivity of the container terminal system introduced AI and ICT technology or other method

When the parallel container-stacking layout was examined in FY2019, we observed that many trucks had to wait for their turn on the terminal premises where cargo volumes of 1,500,000 TEU were handled per year. This meant that deploying the number of RTG cranes there in line with MC-3 and MC-4 would significantly fall short of the required actual cargo throughput. As the terminal had adopted an automated damage inspection system in FY2020, its overall cargo-handling machinery capacity improved, and the on-premises wait time of the trucks, which previously had to wait for ten minutes for their turn on average, was reduced to a short queue of five to six trucks. This improvement is likely attributable to the fact that this model of a container terminal had undergone a major expansion of space that increased its depth from 500 m to 700 m, in addition to its vertical layout where an automated transfer crane (ASC) is always deployed at each lane on the incoming chassis side, and it was assumed that such a terminal layout would require a large initial investment. As described above, AutoMod-powered simulations can enable us to examine various future plans by testing different assumptions. As the current port and harbor plan includes a cargo-handling volume of roughly 1,000,000 TEU per year, there should be sufficient excess capacity according to our simulations.

ⅱ. Proposal of planning method for automated container terminal by quantitative numerical simulation

The PIANC finished its WG208 report titled Planning for Automation of Container Terminals and was set to publish it in March 2021. This 190 pages book contains information on many of the latest cargo-handling machines, and how they could be deployed in combination with various operation systems, etc. Meanwhile, PARI executed a memorandum of understanding (MOU) with the National University of Singapore (NUS) jointly with the Overseas Coastal Area Development Institute of Japan and the Japan Association of Cargo-Handling Machinery Systems. Under the MOU, PARI will form a research alliance not only with the NUS but also other institutions that have executed similar MOUs with the NUS, including the Singapore Maritime Institute and other research centers and universities from Australia, China, Germany, Korea, and the Netherlands, with a view to establishing unified international standards for smart ports. Through this reserch alliance, PARI will function as one of its global partners in the formation of PortML (port mark-up language) standards that will facilitate cooperative interaction and information sharing among various port authorities and users. When this project is completed, it will facilitate the development of innovative digital twin technologies, which will help enhance the global competitiveness of various parties involed in port and other maritime operations in Japan.

Planning for Automation of Container Terminals

ⅲ. Proposal of new technology for container terminal operations

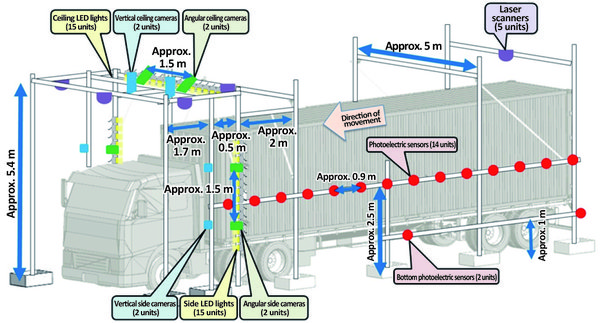

As part of the PRISM (Public/Private R&D Investment Strategic Expansion PrograM) sponsored by the Cabinet Office, we developed an AI-powered image determination system and conducted its data acquisition test at Daikoku Pier in Yokohama Port during FY2020 with a view to implementing the system in actual port operations in the near future. This system is capable of making determinations using both image processing and laser measurement data. In addition, we examined its applicability to PC-18 on Port Island in Kobe Port and prepared its test manual.

Illustration of the container damage inspection system (prototype installed at Yokohama Port)