Major Research 2A Research on Enhancement of Port and Airport Performance for Industrial Competitiveness

Background and Objectives

As Japan's population keeps declining, with the elderly comprising an ever-growing part of its society, and as many infrastructures built in the past continue to deteriorate, technological solutions are needed in order to achieve the following goals: Improve the global competitiveness of the industries in Japan, which are the main source of the country's vitality; identify means of maintaining the functions of the country's ports, harbors, and airports that are essential for sustaining people's living; and maintain, upgrade, and repair the aging infrastructures with limited financial and human resources efficiently and effectively while also trying to extend their lifespans.

Toward the aforementioned goals, PARI has been committed to R&D, etc. for enhancing the functions of ports, harbors, and airports. As for the related subthemes that contribute to raising the country's competitive edge on a global scale such as adoption of policies on internationally strategic ports and enhancement of metropolitan airport functions (improvement of Haneda Airport), etc., we have been conducting R&D activities in a comprehensive manner throughout PARI.

Concerning this particular research theme, we have been developing certain technology that will expand Japan's global competitive advantage, including implementation of ICT, AI, and other information technology at container terminals, and automation of cargo-handling services.

As for PARI's activities to create technology that enables efficient and effective development of port and airport facilities, reports are provided under other research themes. Such activities include formulation of work and inspection methods that are better tailored to port and airport facility operations and work coordination, construction of large-scale facilities for rapid functional improvement, improvement of the seismic performance of facilities, maintenance and management of facilities after they are built, and improvement of existing facilities.

Research Topics

R&D on technology that contributes to improving the capability and functions of ports and airports

- Proposal of evaluation method to estimate the productivity of the container terminal system introduced AI and ICT technology or other method

We will create data models for assessing various facility arrangements at the 1,000-m extension container terminal on New Honmoku Pier at the Port of Yokohama and evaluating the effects of CONPAS, remote-control RTG, and on-dock depots, and suggest suitable functions to be implemented, how to utilize those functions, and arrange facilities based on quantitative evaluation using AutoMod simulations. - Proposal of planning method for automated container terminal by quantitative numerical simulation

We will formulate and suggest quantitative-simulation-based planning technology applicable to container terminals using the quantitative simulations previously run on Tokyo Port, Yokohama Port, Nagoya Port, Osaka Port, Kobe Port, and Hakata Port, while referencing the automated terminal planning guidelines currently being drafted by PIANC for issuance in 2021. - Proposal of new technology for container terminal operations

We will conduct R&D on operation support technology (damage inspection system) pertaining to the container damage inspection system, autonomous control of gantry cranes, remote control of RTG, adoption of AI, etc., which have been funded with PRISM, etc., and will also provide technical support to the government.

Activities in FY 2019

1. Proposal of evaluation method to estimate the productivity of the container terminal system introduced AI and ICT technology or other method

As for our specific activities that were conducted during FY 2019, we focused on New Honmoku Pier at the Port of Yokohama and ran AutoMod simulations on the gates, storage space, and overall pier operation while specifying numbers of GCs, RTGs, and gate lanes based on data from Minami Honmoku Pier MC-1 through 4 of Yokohama Port and assuming cargo-handling throughputs of 1,000,000 TEUs per year and 1,500,000 TEUs per year, which are more than the planned cargohandling capacity. During this process, we created and evaluated data models related to the CONPAS reservation system, the prior clerk system, remote-control RTGs, and on-dock depots.

At a throughput of 1,500,000 TEUs per year, there would be many trucks waiting for their turns on the premises, so we determined that it would be insufficient to have the number of RTGs in proportion to how they are deployed at MC-3 and MC-4. Meanwhile, we also found that a long line of trucks waiting for their turns would still form even at a throughput of 1,000,000 TEUs per year. However, as there was waiting time for both RTG cranes and trucks, such congestion could be improved by devising a method that enables more suitable programming to optimize the matching between different cargo-handling machines. By simply adopting on-dock depots that can actively perform cargohandling at night, these shortcomings could be improved significantly. As for the efficacy of CONPAS, we were able to verify it based on the fact that the amount of cargo passing through the gates had increased.

As for the remote-control RTGs, we found that having one person simultaneously handle operations of four RTG cranes during busy times would create idle time for the RTG cranes.

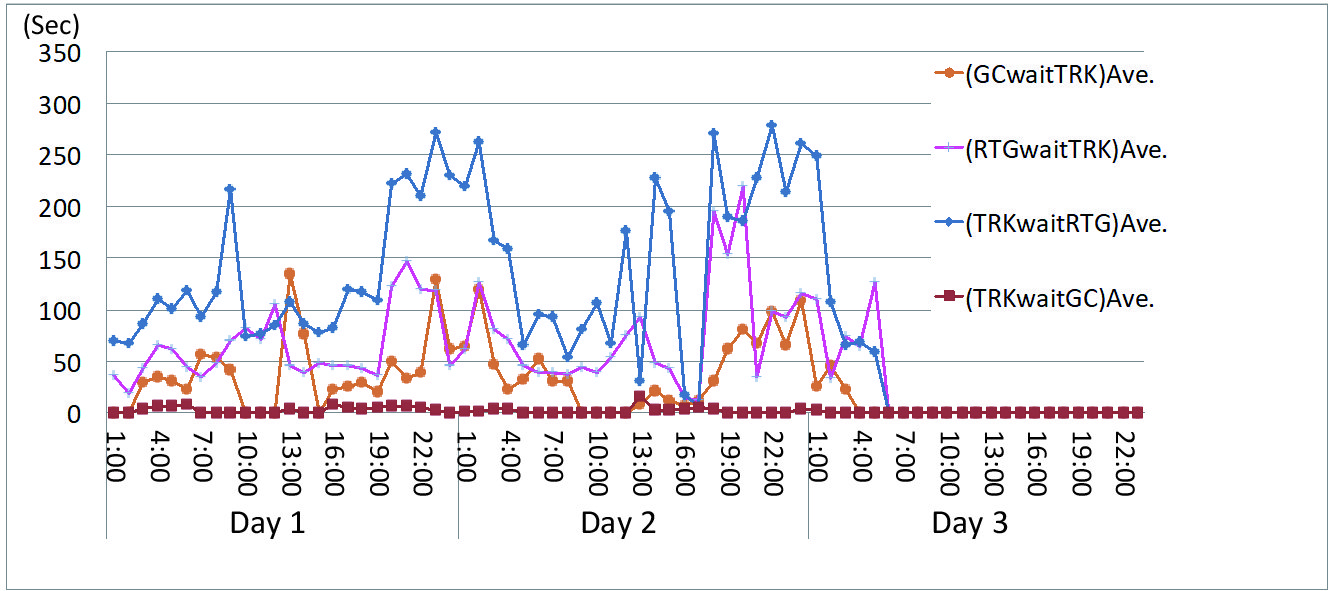

The graph indicates the idle time of different cargo-handling machines waiting for each other. It is apparent that RTG cranes and trucks (TRK) are waiting for each other. (Data is of a certain week where the required cargo capacity is 1,500,000 TEUs per year, assuming use of CONPAS, on-dock depots, and remote-control RTGs.)

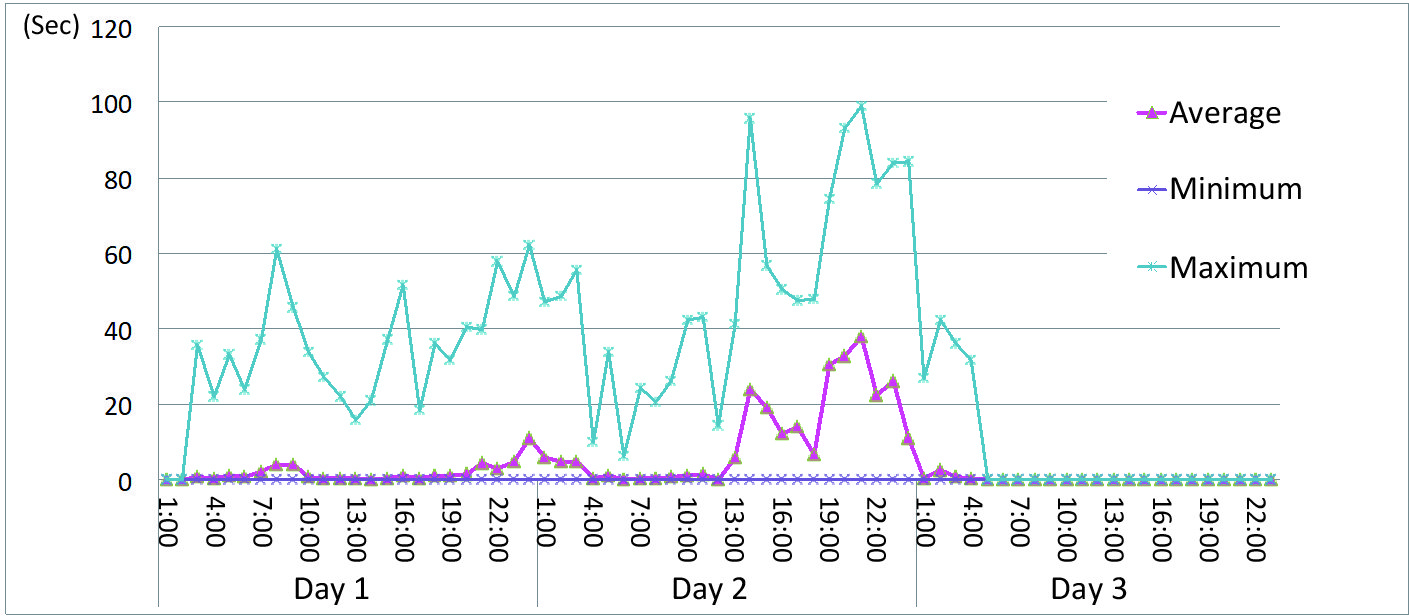

One operator is assigned to four remote-control RTGs. Therefore, if more than one RTG must be operated simultaneously, idle time will occur while waiting for the operator to complete the operation of one crane at a time. The graph indicates such idle time.

As shown above, the on-premises cargo-handling capacity is clearly more critical than the throughput at the gates when large quantities of containers must be handled. Based on this finding, it is considered that use of an AI-powered terminal system that enables programming of efficient operations for the storage space and cargo-handling machines could improve the aforementioned issues.