Major Research 2B Research on Life Cycle Management of Infrastructures

Background and Objectives

The number of port, airport and coastal infrastructures that have been used for a long time is increasing, and yet financial resources and the number of technicians for facility maintenance are limited. Important port, airport, and coastal infrastructure functions should be maintained, and so the strategic maintenance, renewal, and other approaches for such functions are strongly required.

Therefore, we will establish design methods for structures and materials which are excellent in terms of maintenance, and will develop techniques regarding various countermeasures in the maintenance phase.

Research Topics

Research and development comprises the following three subthemes:

1.Research on technologies for prolonging the life of infrastructure

Regarding various construction materials in marine environments, we will conduct research on the following: evaluation of long-term durability, understanding of deterioration mechanisms, and investigation of the prevention effects of protective methods for steel structures. Especially, assuming that infrastructure is used overseas and on remote islands in Japan, we will improve material characteristics and durability under severe environments and under conditions in which low-quality material is used, and will investigate environmental-burden reduction, durability improvement, and environmental coexistence. Regarding airport pavement, we will investigate methods to detect the stripping of asphalt mixture, measures for prevention of such stripping, the improvement of load-bearing characteristics and the rapid repair methods.

2.Research on systems for inspecting and diagnosing infrastructure

We will research and develop the following: inspection and diagnosing techniques using non-destructive and semi-destructive inspection methods and sensors, unmanned investigation devices including ROVs, non-contact thickness measurement system, and others. Especially, we will propose a health-monitoring system which utilizes sensors, as well as monitoring methods specialized for each member type. In addition, for piers, we will establish a scheme for selecting inspection and diagnosing methods according to the performance of structures to be evaluated and the accuracy of expected output.

3.Research on maintenance and management systems for infrastructure

We will conduct accelerated deterioration tests of members of port structures, investigate performance deterioration models which cover the entire lifecycle of structures, and validate such models through exposure tests in actual environments and through on-site investigation. We will also take into account the required properties and utilization of individual structures, budgets, and various limitations, and then suggest strategies of management of port-based and district-based groups of port structures.

Activities in FY 2017

We will use facilities with long-term exposure to predict chloride-induced concrete deterioration, and collect data on the durability of various wood materials.

We aimed to establish a method to predict the deterioration of protective coating methods for steel structures. With this goal, we continuously conducted exposure tests (33 years have passed) regarding protective coating methods for steel pipe piles at Hazaki Observational Pier. We also conducted accelerated deterioration trials to determine the deterioration mechanisms of petrolatum coating methods.

We evaluated the durability of concrete, in which low-grade aggregate (gorgonin) and seawater as mixing water had been used and conducted exposure tests to develop a concrete-curing technique using seawater. In addition, we studied exposed specimens to evaluate the durability of highly corrosion-resistant reinforcing steel (stainless reinforcing steel and epoxy-resin reinforcing steel, and others) and surface coating materials.

We conducted a comparative evaluation through indoor experiments and other approaches regarding aggregate formulation, warm-mix materials, fluidity resistance, peel resistance, water permeability, and other characteristics.

We collected and organized cases of repairing concrete at existing structures. Especially, the local failure of caisson-type side walls caused by repeated collision of wave-dissipating blocks has increased in number recently. Therefore, we draw a flow chart to select the caisson repair method depending on the level of deterioration. Also, we studied the application of a cross-section repair construction method to prestressed concrete (PC) members with chloride-induced corrosion.

Focusing on breakwater caissons, we confirmed the dominant indicators in determining cross-section types for members designed under the current standard; moreover, we studied integrity evaluation methods when the existing caisson's life is extended or when the existing caisson is converted to another use as well as considerations at the time of design and construction.

We proceeded with the following: development of anticorrosion-effect confirmation sensors; establishment of inspection systems for port structures; study on proper sensor placement in RC members for efficient corrosion monitoring; development of steel corrosion sensors in concrete; and investigation of monitoring methods to confirm the effectiveness of new construction methods and materials in pilot projects.

We introduced new operational support functions including a shooting-omission prevention function and an autonomous collision-avoidance function into the ROV for checking the superstructures of piers and then conducted on-site verification. Also, we accumulated data measured through on-site verification on non-contact thickness measurement; moreover, we investigated on-site seasonal biofouling conditions and then set usage conditions.

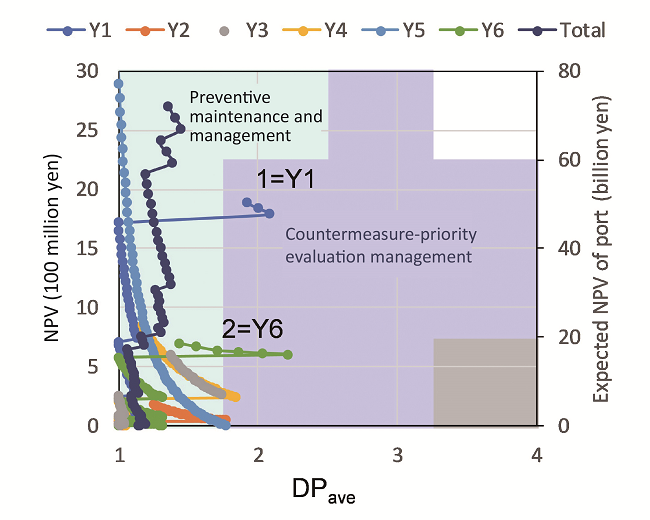

To optimize maintenance and management planning for port facilities, we proposed a priority-setting matrix for maintenance of facilities based on Net Present Value (NPV) and performance deterioration levels. Based on this, we set a model pier, which had been modeled under the assumption that the pier is 1) the preventive maintenance type or 2) the countermeasure-priority evaluation management type, and then conducted case studies of maintenance scenarios, in which LCC and the profit/loss of a facility during the countermeasure construction period are taken into account.

We will use facilities with long-term exposure to predict chloride-induced concrete deterioration, and collect data on the durability of various wood materials.

We aimed to establish a method to predict the deterioration of protective coating methods for steel structures. With this goal, we continuously conducted exposure tests (33 years have passed) regarding protective coating methods for steel pipe piles at Hazaki Observational Pier. We also conducted accelerated deterioration trials to determine the deterioration mechanisms of petrolatum coating methods.

We evaluated the durability of concrete, in which low-grade aggregate (gorgonin) and seawater as mixing water had been used and conducted exposure tests to develop a concrete-curing technique using seawater. In addition, we studied exposed specimens to evaluate the durability of highly corrosion-resistant reinforcing steel (stainless reinforcing steel and epoxy-resin reinforcing steel, and others) and surface coating materials.

We conducted a comparative evaluation through indoor experiments and other approaches regarding aggregate formulation, warm-mix materials, fluidity resistance, peel resistance, water permeability, and other characteristics.

We collected and organized cases of repairing concrete at existing structures. Especially, the local failure of caisson-type side walls caused by repeated collision of wave-dissipating blocks has increased in number recently. Therefore, we draw a flow chart to select the caisson repair method depending on the level of deterioration. Also, we studied the application of a cross-section repair construction method to prestressed concrete (PC) members with chloride-induced corrosion.

Focusing on breakwater caissons, we confirmed the dominant indicators in determining cross-section types for members designed under the current standard; moreover, we studied integrity evaluation methods when the existing caisson's life is extended or when the existing caisson is converted to another use as well as considerations at the time of design and construction.

We proceeded with the following: development of anticorrosion-effect confirmation sensors; establishment of inspection systems for port structures; study on proper sensor placement in RC members for efficient corrosion monitoring; development of steel corrosion sensors in concrete; and investigation of monitoring methods to confirm the effectiveness of new construction methods and materials in pilot projects.

We introduced new operational support functions including a shooting-omission prevention function and an autonomous collision-avoidance function into the ROV for checking the superstructures of piers and then conducted on-site verification. Also, we accumulated data measured through on-site verification on non-contact thickness measurement; moreover, we investigated on-site seasonal biofouling conditions and then set usage conditions.

To optimize maintenance and management planning for port facilities, we proposed a priority-setting matrix for maintenance of facilities based on Net Present Value (NPV) and performance deterioration levels. Based on this, we set a model pier, which had been modeled under the assumption that the pier is 1) the preventive maintenance type or 2) the countermeasure-priority evaluation management type, and then conducted case studies of maintenance scenarios, in which LCC and the profit/loss of a facility during the countermeasure construction period are taken into account.

Optimization of maintenance scenarios for facilities based on NPV and performance deterioration levels