Major Research Development of a method for exploring corrosion in steel rebars inside reinforced concrete and assessing damage in a manner similar to palpation

Electrochemical impedance spectroscopy (EIS) is a technique commonly used to inspect for any corrosion that may be present in steel rebars inside structures made of reinforced concrete. As this technique involves passing electric currents through the steel rebars from the concrete's surface to measure their corrosion condition, it requires connecting a power supply to the rebars through which electricity is to flow. Therefore, it is often necessary to drill holes into parts of the

concrete to attach lead wires to the steel rebars inside, which impedes the inspection operation.

In this research project, we developed a new method that involves installing several electrodes onto the concrete surface to form a separate electric circuit so that EIS can be applied without connecting the steel rebars directly to the power supply. In other words, this method eliminates

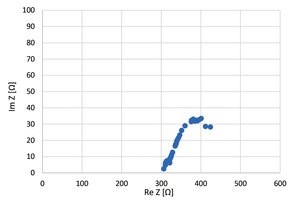

the need to drill holes in the concrete. We then built a corrosion diagnosis unit (Figure 1) incorporating the method and compared the measurement data obtained using the conventional method (direct connection to the steel rebars) and this new method (no direct connection). Figure 2 indicates sample data measured using EIS, which is known as a Nyquist plot. As the Nyquist plots obtained through the two different methods were almost identical, it was proven thatour new method enables EIS without having to drill the concrete.

Figure 1:Corrosion diagnosis unit

incorporating the new method

Figure 2: Data measured by the

new corrosion diagnosis unit

Figure 2: Data measured using

the conventional method