Major Research 2A Research on Enhancement of Port and Airport Performance for Industrial Competitiveness

Background and Objectives

PARI is responsible for research and development to help improve the functions of ports, harbors, and airports across Japan, as part of the country's efforts to improve the international competitiveness of its industries and promote port, harbor, and airport development in an efficient and effective manner, as they are vital to the daily activities of the nation's citizens. PARI's research in these areas covers the following subthemes and goals that are relevant to Japan's international competitiveness, encompassing the country's global strategic port and harbor policy, improvement of airport functions in the Metropolitan Area (improvement of Haneda Airport), infrastructure export capability, etc. These topics are comprehensively studied by various departments of PARI as part of its overall R&D policy.

Research Topics

Research and development were conducted on the following topics to improve the port and airport functions in order to ensure their global competitiveness.

For the particular objective of improving container terminal productivity, we are developing a container damage inspection system, evaluating numerical simulations of terminals where ICT, etc. are used, and studying various implementation plans as part of our efforts to promote digital transformation at ports and harbors, improve their operational efficiency, facilitate the implementation of environmental measures, and enhance their overall functions. In addition, we are conducting research and technological development on a real-time underwater positioning system that will enable remote execution of underwater construction operations, etc.

Activities in FY 2021

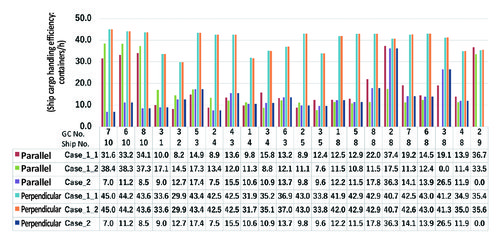

Proposal of evaluation method to estimate the productivity of the container terminal system introduced AI and ICT technology or other method

While our study on the parallel container-stacking layout in FY 2019 revealed that the trucks on standby on the premises became excessive with cargo volumes of 1.5 million TEU per year, as the deployment of a similar number of RTG cranes as MC-3 and MC-4 turned out to be far too few, our study conducted in FY 2020 showed that the gate efficiency would improve if an automated container damage inspection system was used, and the perpendicular (vertical) layout would result in fairly high capacity as the automatic stacking crane (ASC) would be always located on the incoming chassis side in each lane. As it was previously determined that the automated container damage inspection system could not be installed within the width of a lane, our study in FY 2021 had a minimal gate separately installed per lane and compared the perpendicular (vertical) and parallel (horizontal) layouts. We found that while the parallel (horizontal) layout would have significantly negative effects on ship cargo loading/offloading activities unless in-yard cargo handling was optimized, the perpendicular (vertical) layout would result in sufficient capacity. It was also discovered that while no significant difference would arise between reservation rates of 100% and 50% (Case_1_1 and Case_1_2), more operational adjustments had to be made to achieve the desired outcome when using the position data as with Case_2 to have the cranes ready in the container yard in advance. As described above, AutoMod-powered simulations can enable us to examine various future plans by testing different assumptions. As the current Port Plan includes a cargo-handling volume of roughly 1,000,000 TEU per year, there should be sufficient excess capacity according to our simulations.

Proposal of planning method for automated container terminal by quantitative numerical simulation

The PIANC finished its WG208 report titled Planning for Automation of Container Terminals and was set to publish it in March 2021. Our team then made a Japanese-translated version in FY2021, in conjunction with other organizations from the private sector. In addition, our researchers gave keynote speeches at the Japan-ASEAN WS and other events and shared their knowledge with the world on digital twins, emulation, and simulation technologies applicable to container terminals.

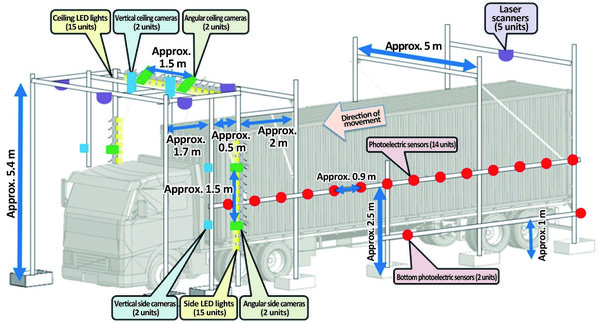

Proposal of new technology for container terminal operations

As part of the PRISM (Public/Private R&D Investment Strategic Expansion PrograM) sponsored by the Cabinet Office, we developed an AI-powered image determination system and conducted its data acquisition test at Daikoku Pier in Yokohama Port during FY2020 with a view to implementing the system in actual port operations in the near future. This system is capable of making determinations using both image processing and laser measurement data. In addition, we examined its applicability to PC-18 on Port Island in Kobe Port and prepared its test manual. In FY 2021, our team aided the MLIT with their on-site empirical test projects.

Illustration of the container damage inspection system (prototype installed at Yokohama Port)

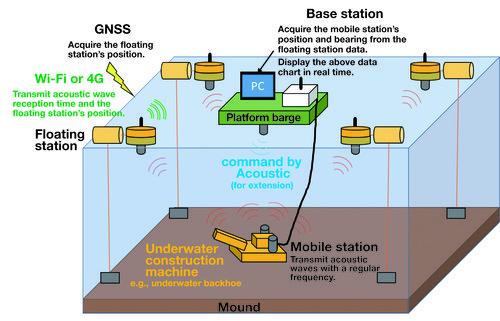

Development of an underwater positioning system

Our team is conducting research and technological development on an underwater positioning system that can acquire the position of any moving objects underwater in real time, eventually with the level of precision that will be required for application to actual construction projects. In FY 2021, we examined the designs of floating, mobile, and base stations that would comprise the system, and created prototypes of some of these components.